A resume of the equations and formulas for the forces and moments on an aircraft-engine mount is presented. In order to ensure low.

Aircraft Engine Mount Frequency Vibration Testing

A vehicles power-plant in particular the way it is mounted to the vehicle body plays a major role in determining the vehicles vibration characteristics.

. Sample V8 Engine Mount Structure 572 Big-Block onto Air Tractor-301 Design Process. Comparison between the measured torque and the sum of the torque-induced mount forces multiplied with their respective levers. Design decides the strength of the engine mount up to which extent it can withstand the load.

They are usually made of rubber and metal. Although they may often appear very simple devices the design and placement of the mounts need to be very carefully optimised in order to achieve satisfactory refinement. Through custom engine mount design there are two processes in which the mount is designed and.

The metal portion connects to the engine on one side and to the frame on the other. How to Choose an Anti-Vibration Mount. Power plant mounting is one of the fundamental design characteristics of a motor vehicle.

Design of Engine Mount Bracket for a FSAE Car Using Finite Element Analysis. This paper reviews and investigates on design and optimization of engine mounts. Motor Mount Design.

Worcester Polytechnic Institute. Dynamic design of automotive systems 321. All engine mount tubing is normalized 4130 alloy steel per MIL-T-6736.

Further information on nonlinear models of hydraulic mounts and vibratory power flow concepts may be found in the. Rear wheel independence needed to be maintained either through a multi-motor design or a differential but. Fig 4a and Fig 4b shows the basic design of engine mount and force vs displacement curve in positive and negative X-direction curve for basic model of engine mount respectively.

Identify the total weight kg of the equipmentmachinery and the number of mountings thatll be required. Calculate the weight of each mounting. While work has been done in the past in the area of engine mount design this dissertation tries to fill in the gap when it comes to designing a comprehensive mounting system that takes into account modeling of the mount characteristics the excitation load present in the.

Frame construction is used throughout the aerospace industry in the creation of welded steel-tube fuselages piston-engine motor mounts ribs and landing gear. In this activity I design a frame assembly for a motor mount structure for a Lycoming O-300 to be installed in a light aircraft. If you do the statics calculation or lay your hands on some material in the lab youll see the 316 thick material is ideal for motor mounts.

Motor mounts engine mounts are used to connect a car engine to the car frame. The first order of business in engine mount design is to determine the initial physical mount configuration. Indeed prefer a rubber mount at higher frequencies.

In order to isolate these vibrations engine mounts are used. There can be 3 to 4 mounts in a car depending on the size and stability of the engine. A Major Qualifying Project.

Marine Propulsion Engine Mount Calculator. The design logic and calculation method for determining mount stiffness and damping for a Powertrain Mounting System PMS based on reductions of vehicle vibration and noise contributed by mounts. Ad Huge Selection of Parts Free Shipping Every Day at CJ Pony Parts.

Mounts has to have the capability to absorb and withstand the vibrational force f or longer periods. The rubber is in-between to provide some flexibility so engine shake doesnt cause the car to shake. Minimized in which the mount parameters are used as design variables.

Material properties for wall thickness under 0187 from MIL-HDBK-5. 18 is a little flimsy and 14 is strong enough for a 200 pound robot so 3. The fatigue strength and durability calculations also have been done for engine safety.

That initial design work depends upon certain basic information including accurate 3D-CAD when available definitions of. The larger the total weight the larger the mountings or the higher the number of mountings needed to reduce the machine vibrations. Sometimes once the engine mount analysis has been completed you may not be able to find the part that you need in a catalog.

Hence the design of engine mounts must be performed with care in order to ensure that each and every one of the engine mounts functions can be accomplished successfully within some performance parameters ranges. Up to 24 cash back Frame design of engine mount. Engine mounts are that crucial parts that help in stabilizing the vehicle and protect the engine from vibration and other nearby parts from damage.

Finite Element Analysis of Engine Mount for Multi Utility Passenger Vehicle. The design requirements for the new electric powertrain were the ability to deliver the peak power of 80kw allowed by rules and meet the mass goal of 23kg. Engine mounts are the key defence in isolating engine forces from the vehicle structure whilst also performing the key function of restraining the engine in the engine bay.

The firewall pickup points. In partial fulfillment of the requirements for the. Hydraulic engine mount pas-sive design.

Engine mount analysis is not only important for existing parts in a catalog it is also important for custom design. Design and Optimization of a Baja SAE Vehicle. Ftu 95 ksi Fty 75 ksi Fcy 75 ksi.

To size a mount for your marine propulsion application enter the total engine gearbox weight in lbs the gear ratio the mounting width distance between mounts port to starboard in inches the engine HP the total of mounts and the engine RPM. To isolate the vibration caused by the engine unbalanced disturbances ie. This document explains how to design motor mounts and other parts for the course design project.

In addition available experimental data have been included to permit the computation of these forces and moments. Submitted to the faculty of. The Engine Mount Design Loads Calculator is a compact engineering windows application for professional and fast evaluation of engine mount design loads for light airplanes with piston engines.

A sample calculation is made and compared with present design conditions for engine mounts p. Comparison between the torque-induced forces in the engine mount as calculated from measurement and approximated from the force in the torque rod. Among them one mount supports the transmission and the rest of the mounts keep the engine in the right.

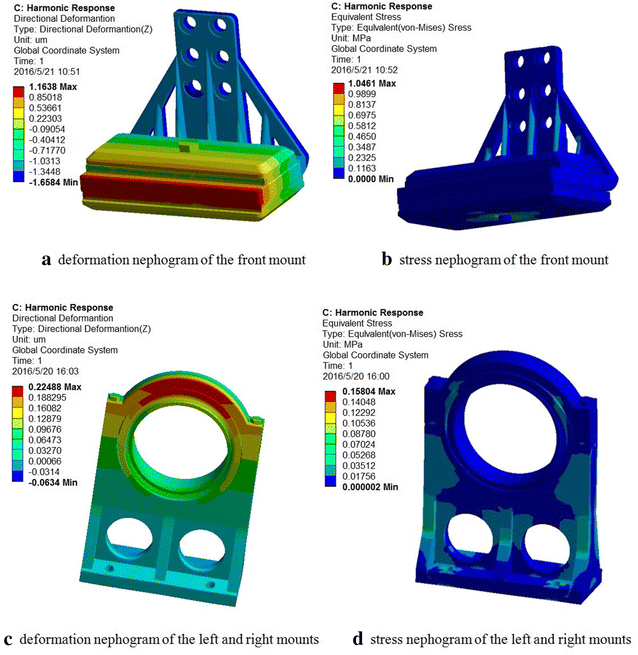

Similarly the results are obtained for two arm three arm four arm filler arm and four arm symmetry engine mounts and they are illustrated in Fig5 to Fig13.

Engine Mounting System Download Scientific Diagram

Schematic View Of The Engine Mounting System Download Scientific Diagram

Engine Mountings An Overview Sciencedirect Topics

Engine Mountings An Overview Sciencedirect Topics

Aircraft Engine Mount Frequency Vibration Testing

Optimization Design And Performance Analysis Of Vehicle Powertrain Mounting System Chinese Journal Of Mechanical Engineering Full Text

Schematic View Of An Engine Mounting System With Four Mounts X F Y F Download Scientific Diagram

0 comments

Post a Comment